5 Essential Elements For gearbox cvt

5 Essential Elements For gearbox cvt

Blog Article

En raison des poulies et de la courroie, il est difficile de canaliser une importante puissance sans avoir de glissement. Il y a également une légère perte de frein moteur par rapport à une transmission automatique conventionnelle.

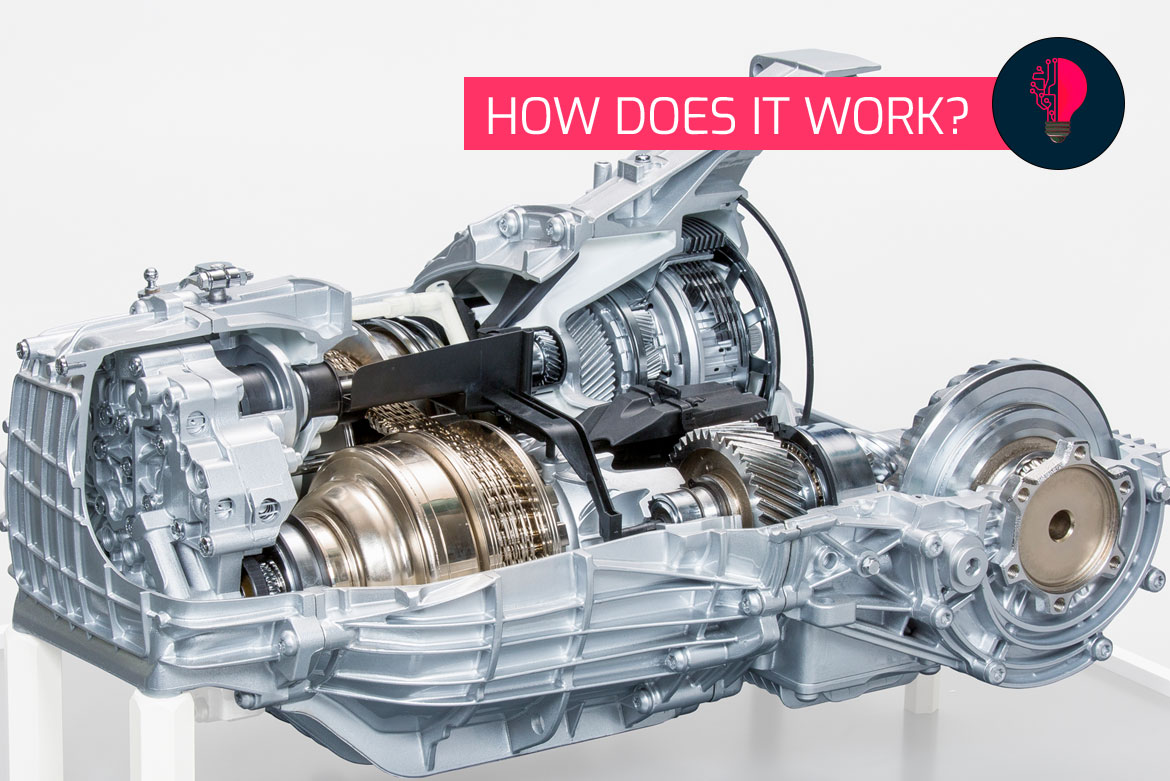

It's the sort of conical pulley which is mounted around the enter shaft and have interior splines meshed While using the shaft splines in this type of manner that it might transfer (also and fro) together with rotates with the enter shaft. the too and fro moment of this shaft in excess of the enter shaft make it achievable to shift equipment ratios.

If you can Dwell with that, and genuinely the only folks who can’t are petrolheads, then a CVT could perfectly be in your case.

The simplicity and stepless nature of CVTs make them an ideal transmission for a range of devices and devices, not merely cars and trucks. CVTs are already utilised For many years in electrical power applications and drill presses.

Typical Fluid Modifications: CVT transmissions demand particular kinds of fluid that have to be checked and replaced based on the maker’s program. Utilizing the right fluid is important, as the wrong type can cause major injury.

We've been sorry that this submit was not handy for yourself! Let us strengthen this post! Explain to us how we can easily improve this submit?

I’ve also go through that site oficial somebody is experimenting which has a tourque converter also. Could you elaborate ? Thanks.

Are there some older versions which have experienced hassle? Obviously. A good way to find out if a design provides a reputation of good reliability is to work with a source like Purchaser Reports or Auto Problems.

A repeatedly variable transmission (CVT) is often a style of automated transmission that's been getting reputation in recent years. In contrast to conventional automatic transmissions that use a set variety of gears, CVTs use a belt and pulley procedure that provides an infinite amount of gear ratios.

At the same time when this enter pulley(sheave) moves, feeding output pulley(sheave) also moves and will come nearer to the fastened output pulley which consequently change the A part of v-formed belt wrapped above the output pulleys in the direction of the higher cross-sectional area with the output conical pulleys and sought after torque ratios is attained.

Programs: Ideal for hefty-duty applications like agricultural and industrial machinery. Its robustness and precise control make it suitable for equipment that needs responsible electrical power and sturdiness.

Exact as shifting input pulley but as opposed to going input shaft, this shaft is put on the correct-hand facet above the output shaft.

A standard automatic gearbox works by using gears to match engine velocity to street velocity. At reduced velocity, the engine turns a little gear and that is connected to a bigger gear that turns the wheels by means of other transmission components.

The design principle dates back to ahead of the 1930s, with the first design meant to transform rotary movement to oscillating movement and back again to rotary motion making use of roller clutches.[18] This design and style stays in creation as of 2017, for use with minimal-pace electric motors.